Product Description

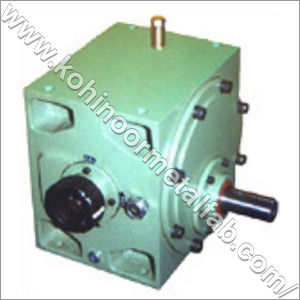

Worm Wheel

Our company is noted as one of the well known manufacturers, exporters and suppliers of Worm Wheel. Available in different range, these wheels are manufactured by our expert professional using latest technology at our in-house production unit. Demanded for their large speed reductions, excellent strength and sharpness, these wheels are suitable for accurate movement of load. Before the end dispatch, Worm Wheel is thoroughly tested using various well defined parameters to ensure the quality.

Further Details:

We manufacture and supply worm wheels for all types of worm gears such as non-throated, single throated and double throated. These wheels are fabricated into various designs, dimensions and other specifications. These wheels possess conclave faces to fit the curvature of the worm pinion to provide high angular velocity between the shafts. We use both ferrous and non-ferrous metals for making our worm wheels.

What is Worm or Worm wheel?

Worm wheel is a type of gear that resembles a screw with parallel helical teeth, and mates with a normal spur gear. It is used when large gear reduction is required. Commonly, a worm gear possesses a reduction ratio of 20:1, and even up to 300:1 or greater.

Features

Highlighting features of our Worm gears are mentioned below:

Various Parameters

While manufacturing the wide array of our worm gears, we consider the following parameters:

Click here for more details.

Advanced Precision EngineeringMeticulously crafted using high-quality bronze for the wheel and steel for the worm, our worm gears are precision-machined to deliver consistent and reliable operation, making them suitable for demanding industrial applications.

Versatile PerformanceWith a power rating up to 5 kW and torque output up to 180 Nm, these worm wheel sets are engineered to accommodate a wide range of machinery, providing flexible integration possibilities for various usage scenarios.

Efficient Motion TransmissionDesigned with an involute tooth profile and optimized for 1440 RPM input speed, our gear systems enable smooth, high-efficiency power transmission, resulting in minimal losses and superior performance.

FAQs of Worm Wheel:

Q: How is the worm wheel manufactured for optimal performance?

A: The worm wheel is precision machined using high-grade bronze for the wheel and hardened steel for the worm, ensuring strength and accuracy. Each gear undergoes quality control processes to achieve consistency, minimizing backlash and maximizing transmission efficiency up to 90%.

Q: What are the typical applications for this worm wheel system?

A: These worm wheels are commonly used in industrial machinery, conveyors, material handling equipment, and automation systems where controlled output speed and high torque are essential. Their robust design makes them suitable for demanding environments.

Q: When should I choose this worm gear arrangement over other gear types?

A: Select this worm wheel system when you require significant speed reduction with compact design, quiet operation, and the ability to transmit high torque at low speeds, especially in situations where self-locking properties are beneficial.

Q: Where are these worm wheels distributed and exported?

A: We distribute, export, and supply these worm wheels throughout India and support international clients, ensuring reliable access to quality gearing components for various industries.

Q: What is the process involved in supplying or sourcing these worm wheels?

A: Customers can reach out to us as a manufacturer, distributor, supplier, or trading partner. We assist with product selection, customization if needed, and offer support throughout procurement, ensuring timely delivery and technical guidance.

Q: How can I ensure proper usage and maintenance of the worm wheel?

A: To maximize service life and efficiency, ensure correct installation, maintain proper lubrication, and perform routine inspections. Following the manufacturers maintenance recommendations will help prevent premature wear and maintain optimal performance.

Q: What are the primary benefits of using this precision machined worm wheel?

A: The main advantages include high efficiency (up to 90%), substantial torque output, compact size, and quiet operation. Additionally, the involute tooth profile ensures reliable power transmission with reduced maintenance requirements.