Product Description

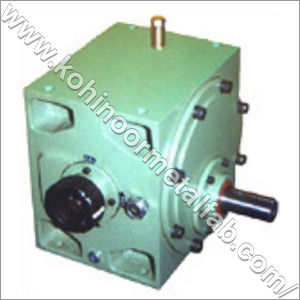

Ground Gears

Bestowed by vast industry experience, we are able to offer a wide range of Ground Gears. These gears are immensely used in chemical plants, mineral plants, sponge iron plants, thermal power station, fertilizer plants, textile plant and paper mills. Manufactured in compliance with industrial standards using cutting-edge technology, clients can buy these gears from us at market leading prices. Known for their effective functionality, high load bearing capacity and smooth finish, Ground Gears are popular in the market.

Further Details:

We specialize in the field of manufacturing and exporting of highest quality ground gears to our clients. We also manufacture custom ground gears as per our client's specifications.

Ground gears are designed to be used in trawling and manufactured with the ideal amount of tip and root relief to ensure quiet operation. Our ground gears are checked and tested thoroughly after the product is finally manufactured to ensure that only the best quality product goes out in the market.

Features

Precision and Durability for Demanding ApplicationsOur ground gears offer exceptional surface quality and dimensional precision, vital for high-load, high-speed conditions in industries such as robotics, automotive, and heavy machinery. Advanced heat treatmentscarburizing and induction hardeningconfer superior wear resistance and longevity. The gears support custom specifications for pitch diameter, face width, torque, and color, ensuring compatibility with diverse industrial setups.

Superior Standards and Wide CompatibilityComplying with global benchmarks like DIN, AGMA, and ISO, our precision ground gears integrate seamlessly into both new designs and retrofit projects. With efficiency rates up to 98% and versatile gearing arrangements, they are ideal for complex applications requiring both clockwise and counter-clockwise rotation. Each gear is meticulously crafted as per client requirements, guaranteeing a bespoke fit for your drive systems.

FAQs of Ground Gears:

Q: How are precision ground gears manufactured to achieve tight tolerances and high surface finish?

A: These gears are produced using advanced grinding processes that follow DIN, AGMA, and ISO standards. Alloy steel blanks undergo precision machining, heat treatment via carburizing or induction hardening, and final grinding to achieve tolerances of DIN 6 or better and surface finish up to Ra 0.8 m.

Q: What industries and applications commonly use these ground spur gears?

A: They are widely used in industrial machinery, automotive transmissions, robotics, and gearboxes due to their high load-carrying capacity, efficient power transmission, and reliability in both clockwise and counter-clockwise operation.

Q: When should I choose ground gears over other gear types?

A: Ground gears are ideal when your application demands high precision, silent operation, low backlash, and maximum efficiencyespecially in heavy-duty or high-speed environments where wear resistance and exact tolerances are critical.

Q: Where can these gears be customized or sourced from?

A: As a manufacturer, distributor, exporter, service provider, supplier, and trader based in India, we offer customization options for module, number of teeth, face width, pitch diameter, torque rating, and gear color to match client specifications.

Q: What is the process for ordering gears with custom specifications?

A: To order, provide your required module, tooth count, dimensions, material, heat treatment preference, and application details. Our engineering team will review your requirements and deliver tailored solutions meeting both performance and compliance standards.

Q: How does heat treatment benefit the functionality of these gears?

A: Carburizing and induction hardening significantly enhance surface hardness (up to 62 HRC), resulting in better wear resistance, longer operational life, and improved load-handling capabilitiesessential for demanding industrial and automotive environments.