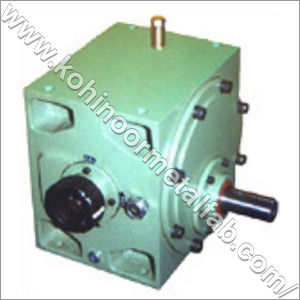

Product Description

Planetary Gearbox

What millennial-old technique are the basics of many of the most innovative technical breakthroughs of this moment? Robotics, 3D printing and new means of transport all have one thing in common: often they are driven by a planetary gearbox. As a supplier of planetary gearboxes, of course we know all ins and outs, but what if you encounter this technique for the first time? We have decided to explain it clearly for all In this article we discuss the basics of the planetary gearbox.

WHAT IS A PLANETARY GEARBOX?

A planetary gearbox is a gearbox with the input shaft and the output shaft aligned. A planetary gearbox is used to transfer the largest torque in the most compact form (known as torque density).

The bicycles acceleration hub is a great example of a planet-wheel mechanism: Have you ever wondered how you can get so much power and capabilities in such a little hub? For a three-speed hub, a one-stage planetary gear system is used, for a five-speed hub a 2-stage. Each planet gear system has a reduction state, a direct coupling and an acceleration mode.

In mathematical terms, the smallest reduction ratio is 3: 1; the largest is 10: 1. At a ratio of less than 3, the sun gear becomes too big against the planet gears. At a ratio greater than 10 the sun wheel becomes too small and the torque will drop. The ratios are usually absolute i.e. an integer number.

Whoever invented the planetary gearbox is not known, but was functionally described by Leonardo ad

WHY IS IT NAMED A PLANETARY GEARBOX?

The planetary gearbox got its name because of how the different gears move together. In a planetary gearbox we see a sun (solar) gear, satellite (ring) gear and two or more planet gears. Normally, the sun-gear is driven and thus moves the planet gears locked in the planet carrier and form the output shaft. The satellite gears have a fixed position in relation to the outside world. This looks similar to our planetary solar system and that is where the name comes from. What helped was that ancient gear constructions were used extensively in astrology for mapping and following our celestial bodies. So it was not such a big step to make.

In practice, we often speak from the perspective of the use of planetary gearboxes for industrial automation. That is why we call the sun-gear the input shaft, the planet gears and carrier the output shaft and the satellite gear (or ring gear) the housing.

POSSIBILITIES OF PLANETARY GEARBOXES

It is possible to realize different speeds and turning directions with the same construction. This can be achieved by, for example reversing the gearbox, which offers the following possibilities:

| Driven side | Solid world | To be driven side | Result |

| Input shaft | Housing | Output shaft | Reduction |

| Input shaft | Output shaft | Housing | Reverse movement + Delay |

| Output shaft | Input shaft | Housing | Delay |

| Output shaft | Housing | Input shaft | Acceleration |

| Housing | Output shaft | Input shaft | Reverse movement + Acceleration |

| Housing | Input shaft | Output shaft | Delay |

| In- and output shaft | N.A. | Housing | 1:1 |

Click here for more details.

Engineered for Superior Precision and StrengthOur planetary gearbox leverages advanced precision machining techniques to provide exceptional accuracy and consistency in gear production. The result is a spur gear profile and planetary arrangement that ensure smooth, reliable power transmission and high load capacity, suitable for demanding industrial setups.

High Output Torque and EfficiencyWith an output torque reaching 600 Nm and operating efficiency up to 98%, our gearbox maximizes power delivery while minimizing energy loss. This efficiency is further complemented by a rated power of up to 15 kW and input speeds of up to 1500 RPM, making it ideal for power-intensive applications.

Comprehensive Support Across IndiaWe serve as a distributor, exporter, manufacturer, supplier, trader, and service provider for planetary gearboxes throughout India. Our extensive network enables prompt response times, technical support, and customized solutions tailored to our clients specific industrial needs.

FAQs of Planetary Gearbox:

Q: How does a planetary gearbox with precision machining benefit industrial applications?

A: A planetary gearbox manufactured with precision machining offers superior gear alignment and reduced backlash, resulting in highly accurate and reliable motion transmission. This translates to consistent, efficient performance even under heavy loads, making it highly beneficial for various industrial uses.

Q: What types of machinery can utilize this planetary gearbox?

A: This gearbox is suitable for a wide range of equipment such as conveyors, robotics, automation lines, and machinery demanding high torque in a compact form factor. Its robust design allows for versatile integration into multiple industrial sectors.

Q: When should I consider using a spur gear tooth profile with a planetary arrangement?

A: You should consider this combination when you need efficient power transfer, reduced maintenance, and high load-bearing capacity within limited installation space. Spur gear profiles in planetary setups are ideal for applications requiring both precision and durability.

Q: Where can these planetary gearboxes be sourced in India?

A: Our planetary gearboxes are available across India through our network as a distributor, exporter, manufacturer, service provider, supplier, and trader. We ensure timely delivery and local support regardless of your region.

Q: What is the process of obtaining customized planetary gearboxes for specific requirements?

A: To obtain customized gearboxes, clients can consult our technical team to discuss specifications such as output torque, power rating, and application environment. Our engineering team uses this information to design and manufacture gearboxes tailored to individual needs.

Q: How should these gearboxes be maintained for optimal efficiency?

A: Regular maintenance involves checking for proper lubrication, inspecting for wear, and ensuring the correct alignment of gears. Adhering to a maintenance schedule as advised by our service team will help maximize efficiency and prolong operational life.