Product Description

Bevel Gears

With the help of our manufacturing unit and experienced personnel, our company brings forth an exclusive range of Bevel Gears. We have with us expert procuring agent who procures certified quality metals from authentic vendors to make these gears in exact adherence with the defined industry norms and standards. Available in different range, these gears are broadly used when the direction of a shaft's rotation needs to be changed. Extensively used in automotive industries, Bevel Gears are demanded for their robust construction and high strength.

Further Details:

Bevel gears connect intersecting axes and come in several types. The pitch surface of bevel gears is a cone. They are useful when the direction of a shaft's rotation needs to be changed. Using gears of differing numbers of teeth can change the speed of rotation. They are usually mounted on shafts that are 90 degrees apart, but can be designed to work at other angles as well.

Bevel gears permit minor adjustment during assembly and allow for some displacement due to deflection under operating loads without concentrating the load on the end of the tooth. For reliable performance, they must be pinned to shaft with a dowel or taper pin. Bevel gear sets consist of two gears of different pitch diameter that yield ratios greater than 1:1.

Types of bevel gears

The bevel gears can be of varied types and the types are known by the teeth of the gears. Different varieties are:

-

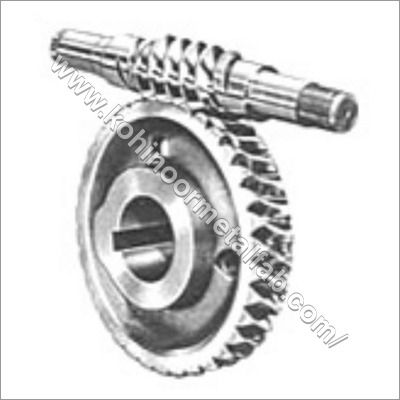

Spiral Bevel Gears:

Spiral bevel gears have spiral angles, which gives performance improvements. The contact between the teeth starts at one end of the gear and then spreads across the whole tooth. In both the bevel types of gears the shaft must be perpendicular to each other and must be in the same plane.

-

Hypoid Bevel Gears:

The Hypoid bevel gears can engage with the axes in different planes. This is used in many car differentials. The ring gear of the differential and the input pinion gear are both hypoid. This allows input pinion to be mounted lower than the axis of the ring gear. Hypoid gears are stronger, operate more quietly and can be used for higher reduction ratios. They also have sliding action along the teeth, potentially reducing efficiency.

Click here for more details.